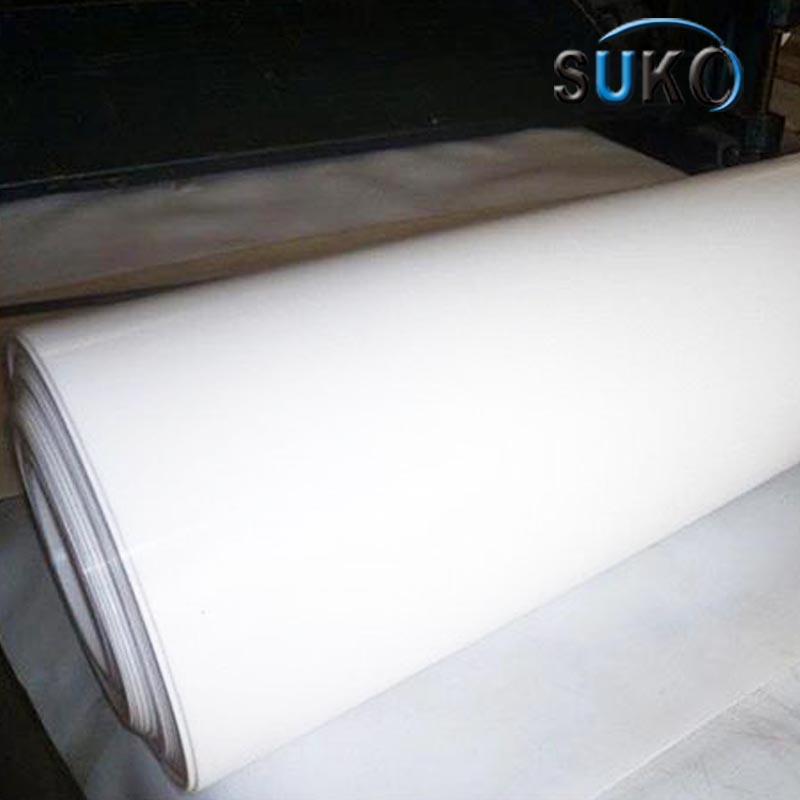

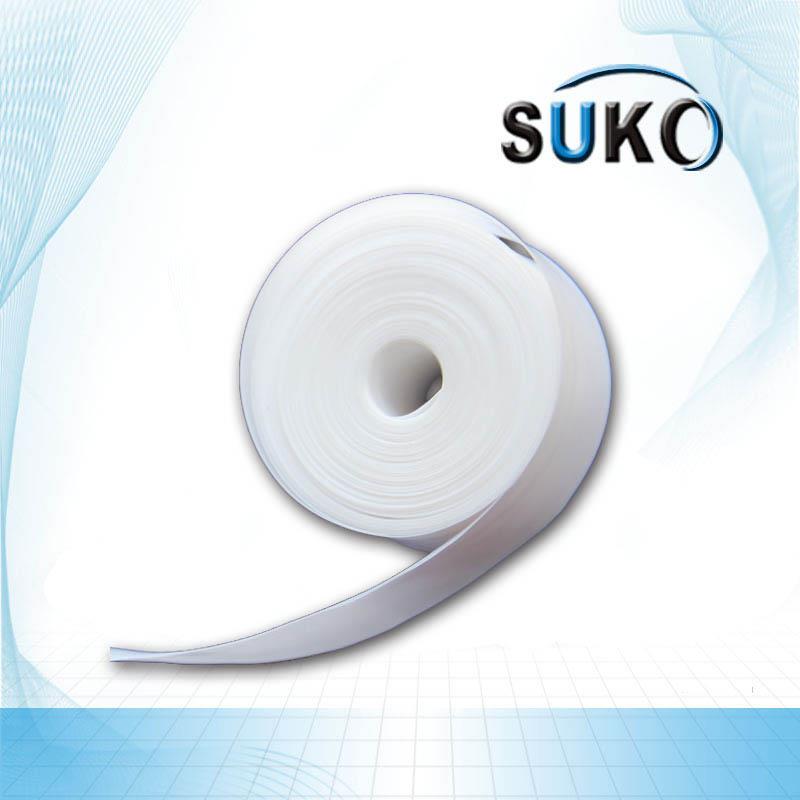

Skived PTFE Sheets .001" to .250" Thick

Skived PTFE Film sheets are manufactured from virgin PTFE resins which are molded, sintered, and skived to the appropriate thickness. Both PTFE sheets and film are widely used in a number of industries due to the material’s outstanding characteristics, including heat and chemical resistance, dielectric strength and anti-stick properties. Both sheets and film may also be chemically etched on one or both sides for bondability.

Skived PTFE Film sheets are available in thicknesses ranging from 0.0115″ to 0.25″ and in widths of 12″, 24″, 36″, and 48″. PTFE film is supplied either in sheet or continuous roll form. Slit widths are available in thicknesses ranging from 0.001″ to 0.062″ and to the exacting tolerances of the wire and cable, and electronic industries.

.001″ to .250″ Thick:

| Thickness (inches) | Tolerance +/-(inches) | LBS Per Sq FT |

| .0005 | .0001 | .006 |

| .001 | .0005 | .012 |

| .002 | .0005 | .024 |

| .003 | .0005 | .036 |

| .004 | .0005 | .048 |

| .005 | .0005 | .060 |

| .006 | .0005 | .072 |

| .010 | .001 | .120 |

| .015 | .0015 | .180 |

| .020 | .002 | .240 |

| .025 | .005 | .300 |

| .040 | .005 | .480 |

| .050 | .005 | .600 |

| .062 | .005 | .720 |

| .080 | .005 | .960 |

| .093 | .005 | 1.120 |

| .125 | .010 | 1.500 |

| .156 | .010 | 1.900 |

| .187 | .015 | 2.250 |

| .250 | .020 | 3.000 |

STANDARD PTFE FILLER FEATURES:

|

Glass Fiber |

Increases compressive strength, rigidity and wear. Reduces creep and cold flow Minimal effect on chemical and electrical properties |

|

Carbon |

Increases compressive strength, hardness, wear, and load properties. Good chemical resistance Various types and amounts of carbon can be added to alter conductivity |

|

Graphite |

Reduces coefficient of friction Reduces initial wear Increases strength |

|

Molybdenum Disulfide |

Increases hardness, stiffness, and wear Minimal effect on chemical and electrical properties |

|

Bronze |

Increases hardness and wear resistance Increases dimensional stability and compressive strength Not suitable for corrosive or electrical applications |

Satisfied with the product

Satisfied with the product

todo bien muy buen servicio

todo bien muy buen servicio

Good seller. No problems with delivery, item delivered was as described